Setting up warehouse operations is not an easy task. If warehouses are set up in the best way possible, storing items is very easy. The problem arises if warehousing is done haphazardly, with little attention paid to the routines and procedures of the staff operating in the facility. How to: Organize Warehouse The best way to organize a warehouse is to make the process easier for the warehouse employees. Once an order comes into the warehouse, the process of receiving and storing items should be well-oiled by the staff.

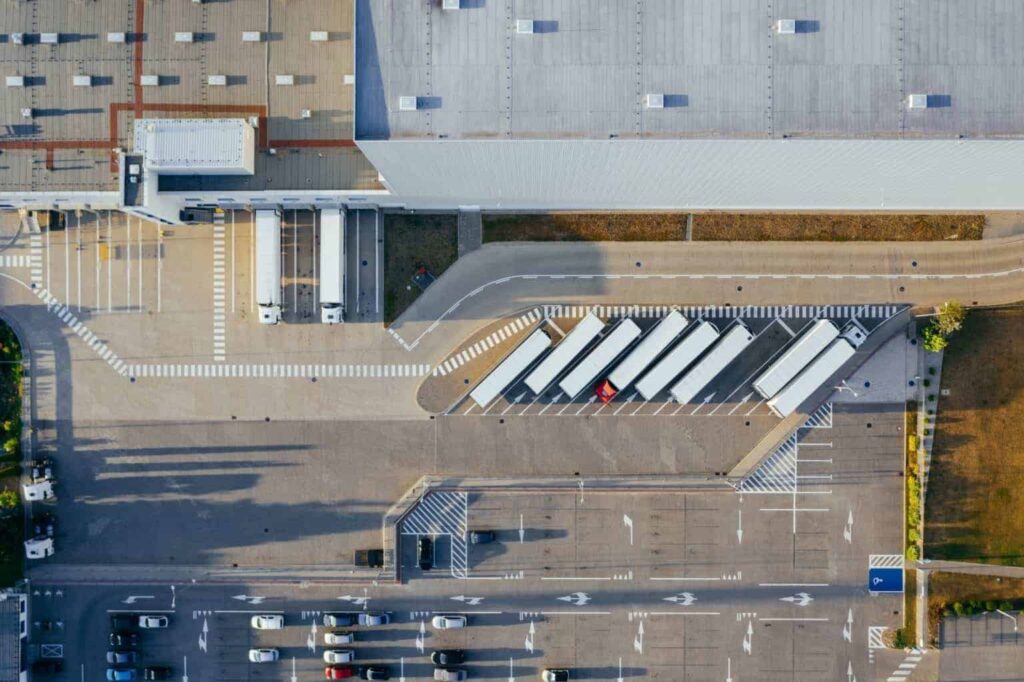

Set Up Location: The first thing to do in the warehouse management is to set up a specific location. Many companies choose a single location for all of their products. However, it is a better choice to have multiple locations where you can cater to a number of customers who buy goods in bulk.

The set-up locations should also have easy access to the rest of the warehouse management. In other words, set up locations near the front and sides of the warehouse are always better because it reduces the movement of heavy goods during rush hour. The set up area should include shelving units for stacking goods, an organized inventory tracking system, a large number of pallet racks and heavy duty plastic packaging machines.

Warehouse Physical Inventory Dump Bins physical inventory bin system is a must-have feature for any warehouse. This system is very important because it eliminates the need for physically dumping heavy goods to the floor. If there is a problem with a stack of goods, the physical inventory system will automatically dump the goods to the chutes, eliminating the need for any human intervention. Other features in this set up include a control system to monitor dumping of goods, a storage bin for goods placed on pallets, and an efficient flow of goods through the warehouse.

Directed put-away and non-directed put-away are also must-haves for any warehouse locations. They reduce the chances of theft as well as damage to the goods. Non-directed put-away is where goods are simply stored in bins; however, goods can be directed to specific departments or directly to the employees. Meanwhile, directed put-away is where products are stacked in large shelves. However, it comes with a risk of over-stacking, so it is advisable to have someone on staff who will be able to manage and oversee the stocks.

The third part of any efficient set up is the workflow management. This includes things like tool and die set up, packing, pick and pack, and labeling and labelling activities. In addition to these major activities, the set up warehouse processes can also include wire and cable assemblies, cleaning, and miscellaneous duties. All of these are vital to ensure that the warehouse operations run smoothly. Depending on the business, each of these may differ greatly, thus having a good set of warehouse processes in place will greatly help the set up warehouse processes in running as smoothly as possible.

Setting up an effective set up warehouse requires careful planning. This should take into consideration factors such as the type of goods that will be stored, the amount of stock that the warehouse holds, and the workflow requirements of the set up warehouse itself. In order to set up an effective set up warehouse, every aspect of the operation should be carefully considered and implemented. This will then include a comprehensive inventory storage analysis to determine what the set up warehouse holds and how it can be used best.

There are a number of factors involved when setting up warehouse locations. These factors include the amount of stock that is needed to store, warehouse location, amount of space available, and the type of goods that will be held. Some of these set up warehouse locations may even be used as primary locations if they prove to be profitable enough. Warehouse processes will be determined by the needs of the operation as well as what kinds of merchandise need to be stored. It will help for someone to consider all of these things carefully. This will help to ensure that the set up warehouse locations that are chosen are perfect.

Finding a Reliable Airport Transfer Online

Finding a Reliable Airport Transfer Online