A die is a metal block or plate that is used to shape and form various materials, such as metal, plastic, or wood, into a specific shape or design. Dies are an essential tool in the manufacturing process, allowing companies to produce identical parts with exacting specifications. The die is essentially a negative image of the desired shape, and when a material is pressed or stamped into the die, it takes on the shape of the die.

The Importance of Dies in Manufacturing

Dies play a critical role in the manufacturing process, enabling companies to produce high-quality products with precision and accuracy. By using a die, manufacturers can ensure that every part produced is identical, reducing the risk of defects and improving overall product quality. Dies are also essential for producing complex shapes and designs, which would be difficult or impossible to achieve through other manufacturing methods.

Applications of Dies in Various Industries

What is a die are used in a wide range of industries, including automotive, aerospace, consumer goods, and construction. In the automotive industry, dies are used to produce car parts, such as engine blocks, cylinder heads, and body panels. In the aerospace industry, dies are used to produce aircraft parts, such as engine components and satellite components. In the consumer goods industry, dies are used to produce household items, such as appliances, furniture, and electronics.

Types of Dies

There are several types of dies, each designed for specific applications and materials. For example, a stamping die is used to produce flat or 2D parts, while a forging die is used to produce 3D parts. A casting die is used to produce parts through the casting process, where molten metal is poured into the die to create the desired shape. A machining die is used to produce parts through machining processes, such as milling or turning.

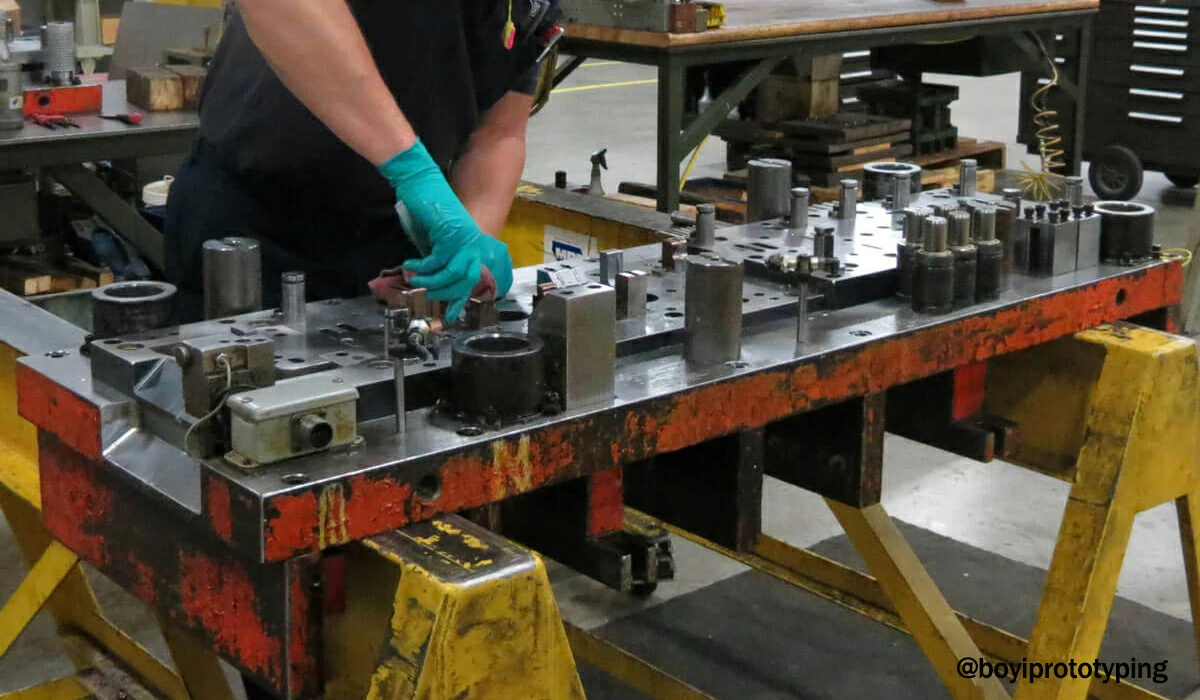

Die Making Process

The die making process involves several stages, including design, material selection, machining, and testing. The design stage involves creating a blueprint of the die, taking into account the specific requirements of the product. The material selection stage involves choosing the right material for the die, based on factors such as durability, corrosion resistance, and thermal conductivity. The machining stage involves cutting and shaping the material into the desired shape, using various machining processes. The testing stage involves verifying that the die meets the required specifications and standards.

Benefits of Using Dies in Manufacturing

Using dies in manufacturing offers several benefits, including improved product quality, increased efficiency, and reduced costs. By producing identical parts with exacting specifications, companies can reduce the risk of defects and improve overall product quality. Dies also enable companies to produce complex shapes and designs, which can be! difficult or impossible to achieve through other manufacturing methods. Additionally, dies can be used to produce large quantities of parts, reducing production costs and improving efficiency.

Conclusion

In conclusion, a die is a metal block or plate used to shape and form various materials into a specific shape or design. Dies are an essential tool in the manufacturing process, enabling companies to produce high-quality products with precision and accuracy. By understanding the applications of dies in manufacturing, companies can improve product quality, increase efficiency, and reduce costs. Whether it’s in the automotive, aerospace, or consumer goods industry, dies play a critical role in shaping the world around us.