The production of sanitary napkins is a critical aspect of the hygiene industry. With the increasing awareness of women’s health and hygiene, the demand for high-quality sanitary napkins has surged. Welldone Machine has established itself as a leader in this field by providing advanced machinery that enhances the production process. This article provides an overview of the sanitary napkin production process using Welldone Machine technology.

Raw Material Selection

The first step in the sanitary napkin production process is the selection of raw materials. Welldone Machine uses high-quality materials to ensure the effectiveness and comfort of the final product. The primary materials include absorbent core materials, non-woven fabrics, and adhesive components. The choice of materials is crucial as it directly impacts the absorbency, softness, and overall performance of the sanitary napkins.

Material Preparation

Once the raw materials are selected, they sanitary napkins production machine before entering the production line. This stage involves cutting and processing the materials to the required specifications. Welldone Machine has integrated automated systems that streamline this preparation process. By ensuring precise measurements and cuts, the machines minimize waste and enhance efficiency, setting the stage for a smooth production flow.

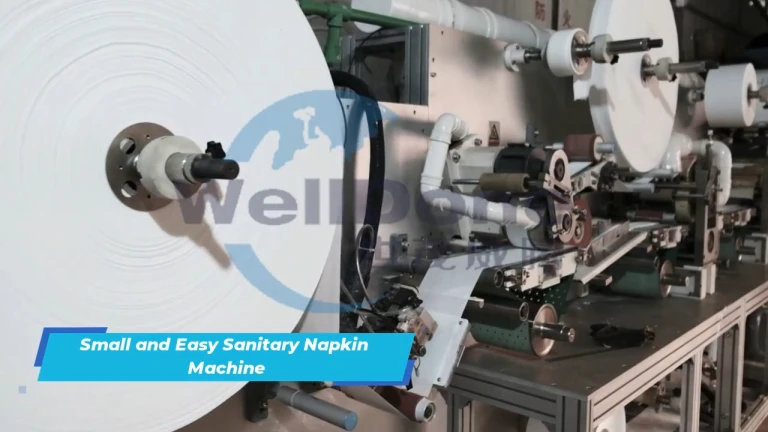

Production Line Setup

The production line setup is a vital aspect of the manufacturing process. Welldone Machine designs its production lines to be flexible and adaptable to different product specifications. The machines can be configured to produce various sizes and types of sanitary napkins, catering to diverse consumer needs. This flexibility allows manufacturers to respond quickly to market demands and preferences.

Forming the Absorbent Core

The absorbent core is the heart of the sanitary napkin, responsible for moisture absorption and retention. Welldone Machine employs advanced technology to form the absorbent core efficiently. The process involves layering the absorbent materials and ensuring they are securely bonded. This step is critical as it determines the overall absorbency and comfort of the final product.

Adding the Top Sheet

The top sheet is the layer that comes into direct contact with the skin. It is essential for providing comfort and preventing leakage. Welldone Machine’s production process includes the precise application of the top sheet over the absorbent core. The machines ensure that the top sheet is aligned correctly and securely attached, maintaining the integrity of the sanitary napkin.

Sealing and Cutting

After the top sheet is applied, the next step is sealing and cutting the sanitary napkins into individual units. Welldone Machine utilizes high-speed sealing technology to ensure that each napkin is securely sealed, preventing any leakage. The cutting process is also automated, allowing for consistent sizing and shape across all products. This level of precision is crucial for maintaining quality control.

Packaging Process

Once the sanitary napkins are produced, they need to be packaged for distribution. Welldone Machine has developed efficient packaging solutions that ensure the products remain hygienic and protected. The packaging process includes wrapping the napkins in protective materials and labeling them appropriately. This step is essential for providing consumers with clear information about the product.

Quality Control Measures

Quality control is a critical component of the sanitary napkin production process. Welldone Machine implements rigorous quality control measures at every stage of production. This includes testing raw materials, monitoring the production process, and inspecting the final products. By ensuring that each sanitary napkin meets high-quality standards, Welldone Machine helps manufacturers build trust with their consumers.

Sustainability Practices

In today’s environmentally conscious market, sustainability is a key consideration in manufacturing. Welldone Machine is committed to sustainable practices throughout the production process. The machines are designed to minimize waste and energy consumption. Additionally, the company encourages the use of biodegradable materials in the production of sanitary napkins, contributing to a more sustainable future.

Training and Support for Manufacturers

Welldone Machine understands that the successful implementation of its technology requires proper training and support. The company offers comprehensive training programs for manufacturers to ensure that their staff can operate the machinery effectively. Ongoing support is also provided to assist with troubleshooting and maintenance, helping manufacturers maximize the potential of their production lines.

Conclusion

In conclusion, the sanitary napkin production process using Welldone Machine technology is a well-structured and efficient operation. From raw material selection to packaging, each step is designed to ensure high-quality products that meet consumer needs. With a focus on automation, quality control, and sustainability, Welldone Machine continues to lead the way in the sanitary napkin manufacturing industry. As the demand for hygiene products grows, the innovations introduced by Welldone Machine will play a crucial role in shaping the future of this essential market