Custom parts machining solutions are a critical component of modern manufacturing, enabling companies to produce complex designs with precision and accuracy. In today’s fast-paced business environment, companies must be able to quickly and efficiently produce high-quality parts and components to stay ahead of the competition. Custom parts machining solutions provide a way for companies to achieve this goal, by offering a range of machining services that can be tailored to meet specific needs and requirements.

The Benefits of Custom Parts Machining Solutions

Custom parts machining solutions offer numerous benefits, including increased precision, improved product quality, and reduced production costs. By using advanced machining technologies, such as CNC machining and 3D printing, companies can produce complex designs with a high degree of accuracy and precision. This enables companies to improve the overall quality of their products, while also reducing the risk of errors and defects. Additionally, custom parts machining solutions can help companies to reduce their production costs, by minimizing waste and optimizing production processes.

Applications of Custom Parts Machining Solutions

Custom parts machining solutions have a wide range of applications across various industries, including aerospace, automotive, medical, and consumer products. In the aerospace industry, custom parts machining solutions are used to produce complex aircraft components, such as engine mounts and satellite components. In the automotive industry, custom parts machining solutions are used to produce engine components, transmission parts, and suspension components. In the medical industry, custom parts machining solutions are used to produce surgical instruments, medical implants, and diagnostic equipment.

The Role of Advanced Machining Technologies in Custom Parts Machining Solutions

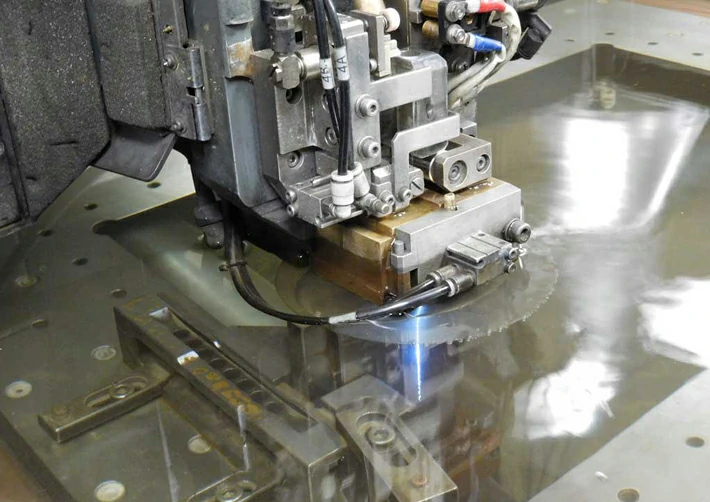

Advanced machining technologies, such as CNC machining and 3D printing, play a critical role in custom parts machining solutions. These technologies enable companies to produce complex designs with a high degree of accuracy and precision, while also reducing production costs and improving product quality. CNC machining uses computer-controlled machines to remove material from a workpiece, creating the desired shape and design. 3D printing, on the other hand, uses a layer-by-layer approach to create complex geometries and designs.

Materials Used in Custom Parts Machining Solutions

Custom parts machining solutions can be performed on a wide range of materials, including metals, plastics, and composites. The choice of material depends on the intended application, desired properties, and machining requirements. Common materials used in custom parts machining solutions include aluminum, steel, stainless steel, titanium, and copper. Plastics, such as polycarbonate and ABS, are also widely used, particularly in medical and consumer product applications. Composites, including carbon fiber and fiberglass, offer exceptional strength-to-weight ratios, making them ideal for aerospace and automotive applications.

The Importance of Quality Control in Custom Parts Machining Solutions

Quality control is a critical aspect of custom parts machining solutions, ensuring that the final product meets the required specifications and standards. To ensure quality, companies must implement rigorous quality control measures, including inspection and testing. This involves checking the part for dimensional accuracy, surface finish, and material properties. Any defects or irregularities must be addressed promptly, and corrective action must be taken to prevent future occurrences.

The Future of Custom Parts Machining Solutions

The future of custom parts machining solutions looks bright, with advancements in technology and manufacturing processes expected to drive growth and innovation. The increasing use of automation and robotics is expected to improve efficiency and reduce production costs. The development of new materials and manufacturing techniques is expected to expand the range of applications for custom parts machining solutions. As companies continue to push the boundaries of product design and innovation, the demand for custom parts machining solutions is expected to increase, driving growth and development in this exciting field.

Conclusion

Custom parts machining solutions are a powerful tool for companies looking to produce complex designs with precision and accuracy. By offering a range of machining services that can be tailored to meet specific needs and requirements, custom parts machining solutions provide a way for companies to improve product quality, reduce production costs, and stay ahead of the competition. Whether you are a designer, engineer, or manufacturer, custom parts machining solutions offer a world of possibilities for creating complex, high-quality parts and components that meet exact specifications.