Custom plastic mold fabrication is a crucial step in the production of plastic components for various industries. Every project has unique requirements and challenges, and having custom injection mold tooling ensures that these specifications are met with precision and efficiency.

The Importance of Custom Injection Mold Tooling

When it comes to specialized projects that require custom plastic mold fabrication, it is essential to work with a team of experienced professionals who understand the intricacies of the process. From design to fabrication, every step must be carefully planned and executed to deliver excellence in every design.

Advantages of Custom Injection Mold Tooling

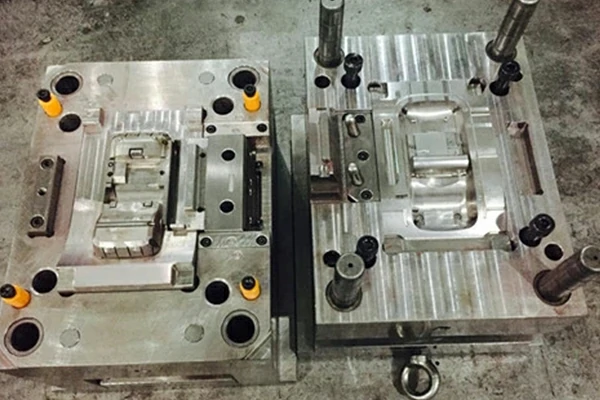

One of the key advantages of custom injection mold tooling is the ability to create molds that are tailored to the specific needs of the project. Whether it is a complex shape, intricate details, or specific material requirements, custom mold fabrication allows for the production of molds that are customized to the project’s exact specifications.

Collaboration and Customization

By working closely with the client throughout the design and fabrication process, custom plastic mold fabrication ensures that every detail is accounted for and that the final product meets or exceeds expectations. This level of customization not only results in a high-quality end product but also ensures that the production process is as efficient and cost-effective as possible.

Streamlining the Production Process

In addition to meeting specific design requirements, custom injection mold tooling can also help streamline the production process by reducing the cycle time and enhancing the overall efficiency of the manufacturing process. By optimizing the design of the mold and using advanced manufacturing techniques, custom plastic mold fabrication can help increase productivity and reduce lead times.

Flexibility and Adaptability

Furthermore, custom mold fabrication allows for greater flexibility in production, as changes can be made to the mold design quickly and easily to accommodate modifications or improvements. This adaptability is crucial for projects that may require frequent design changes or updates throughout the production process.

Consistency and Repeatability

Custom plastic mold fabrication also ensures consistency and repeatability in the production of plastic components, which is critical for maintaining quality standards and meeting the demands of the market. By creating molds that are tailored to the specific requirements of the project, manufacturers can produce high-quality parts consistently and reliably.

Conclusion

Overall, custom injection mold tooling offers efficient solutions for specialized projects by delivering excellence in every design. From intricate details to complex shapes, custom plastic mold fabrication ensures that every aspect of the project is carefully considered and executed to achieve the desired results. By working with experienced professionals who understand the intricacies of the process, clients can be confident that their custom plastic mold fabrication project will be completed with precision, efficiency, and excellence.