Creating a threaded hole is a crucial step in many manufacturing and engineering applications. A threaded hole provides a secure connection between two components, allowing them to be joined together with a screw or bolt. In this article, we will explore the process of making a threaded hole for secure connections.

Understanding Threaded Holes

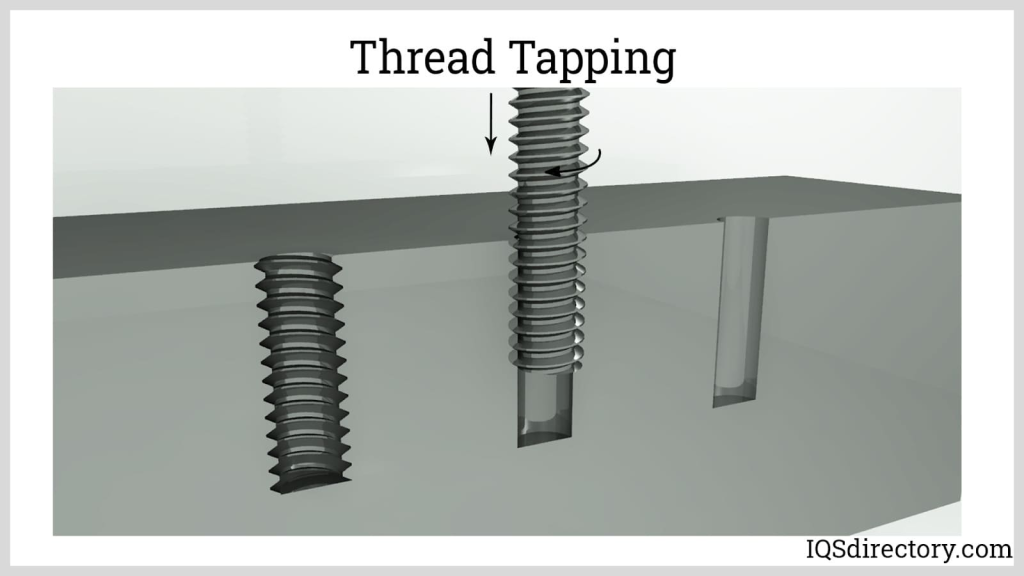

A threaded hole is a hole that has been drilled and then threaded using a tap. The tap cuts threads into the material, creating a hole that can be used to attach other parts or components. threaded hole are commonly used in materials such as metal, plastic, and wood.

The first step in making a threaded hole is to choose the right material. The material should be strong enough to support the weight and stress of the connection, and it should be able to withstand the forces that will be applied to it.

Drilling the Hole

Once the material has been selected, the next step is to drill the hole. The hole should be drilled using a drill bit that is slightly smaller than the tap that will be used to thread it. This will ensure that the threads are cut correctly and that the hole is not too large for the screw or bolt.

Tapping the Hole

After the hole has been drilled, it’s time to tap it. Tapping involves cutting threads into the material using a tap. The tap should be inserted into the hole and turned slowly until it reaches the desired depth.

Thread Cutting

As the tap cuts through the material, it creates threads on both sides of its path which allows screws bolts etc., securely fasten themselves within those internal grooves thus giving us our desired result i.e., creation of an effective & efficient way for joining multiple parts together!

Factors Affecting Thread Quality

There are several factors that can affect thread quality when making a threaded hole. These include tool selection (tap & drill), proper coolant usage during operation – ensuring clean dry environment around work area prevents any contamination from affecting final product finish dimensions!

Common Applications of Threaded Holes

Threaded holes have numerous applications across various industries including aerospace automotive construction manufacturing where high strength connections required between different components parts like engine mounts gearboxes etc.

Tips for Making High-Quality Threaded Holes

To make high-quality threaded holes requires attention detail patience skill practice following some simple guidelines such as selecting correct tools materials taking necessary safety precautions monitoring operations closely leads better results over time!

Conclusion

In conclusion creating effective secure connections via threading process demands knowledge understanding what works best under specific conditions given project requirements Having gained insight about these fundamental principles now go ahead confidently tackle even most challenging tasks knowing exactly how create durable long lasting joints every single time!