Nuts and bolts are two of the most common fasteners used in construction, manufacturing, and various other industries. These small yet crucial components play a significant role in holding together different parts of a structure or machinery.

When it comes to nuts, they are typically hexagonal in shape with an interior thread that matches the thread on the bolt. Nuts are used to secure the bolt in place by screwing onto it, creating a tight and secure connection. Nuts are available in various sizes and materials, such as steel, brass, and stainless steel, to meet different requirements based on the application.

On the other hand, bolts are the threaded fasteners that are inserted through holes in various materials and tightened with a nut. Bolts come in different lengths and diameters, with a variety of heads, including hexagonal, square, and round. The threaded portion of the bolt is designed to match the internal threads of the nut, allowing the two components to be securely fastened together.

Now, let’s talk about the roles and applications of nuts and bolts in different industries. In construction, nuts and bolts are commonly used to hold together structural beams, columns, and other components of buildings and bridges. The high strength and durability of nuts and bolts make them ideal for supporting heavy loads and withstanding external forces, such as wind and seismic activity.

In manufacturing, nuts and bolts are essential for assembling machinery, equipment, and various mechanical components. The precision and accuracy of nuts and bolts ensure that the parts fit together seamlessly, creating a reliable and robust system. Whether it’s a conveyor belt system in a factory or an engine in an automobile, nuts and bolts play a crucial role in ensuring the functionality and safety of the equipment.

In the automotive industry, nuts and bolts are used to assemble vehicles, ranging from cars and trucks to motorcycles and bicycles nut vs bolt. The different sizes and types of nuts and bolts allow manufacturers to create complex structures with ease, enabling them to produce high-quality vehicles that meet rigorous safety standards and performance requirements.

In the aerospace industry, nuts and bolts are critical for assembling aircraft, spacecraft, and satellites. The lightweight yet strong materials used in aerospace nuts and bolts are designed to withstand extreme conditions, such as high temperatures, pressure changes, and vibrations. The reliability and precision of nuts and bolts in aerospace applications are essential for ensuring the safety and success of missions in space.

Overall, nuts and bolts are versatile fasteners that play a vital role in the construction, manufacturing, automotive, and aerospace industries. Their strength, durability, and precision make them indispensable for holding together various components and structures, ensuring the safety, reliability, and functionality of machines and equipment. Whether it’s building a skyscraper, manufacturing a car, or launching a satellite into space, nuts and bolts are essential components that we rely on every day.

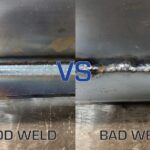

Bad Welding vs Good Welding: Techniques and Outcomes

Bad Welding vs Good Welding: Techniques and Outcomes