In the world of modern machining, precision and efficiency are key factors that can make or break a manufacturer’s success. That’s where advanced carbide inserts come into play, offering a range of advantages that can help optimize machining processes in various industries.

The Benefits of Carbide Inserts: Hardness and Wear Resistance

One of the main benefits of using carbide inserts is their exceptional hardness. Made from a combination of tungsten, carbon, and other materials, carbide inserts are incredibly tough and resistant to wear and tear. This means that they can withstand high levels of heat and friction generated during machining operations, ensuring longevity and consistency in performance.

Improved Cutting Speeds and Precision

The hardness of carbide inserts also enables them to maintain sharp cutting edges for longer periods of time. This results in improved cutting speeds and feeds, as well as higher levels of precision and accuracy in the finished product. With carbide inserts, manufacturers can achieve tighter tolerances and smoother surface finishes, leading to enhanced quality and customer satisfaction.

Heat Resistance and Thermal Deformation

In addition to their hardness, carbide inserts are also known for their exceptional heat resistance. This property allows them to dissipate heat more effectively during machining, reducing the risk of thermal deformation and damage to the workpiece. As a result, manufacturers can push the limits of cutting speeds and feeds, maximizing productivity and efficiency in their operations.

Chip Control and Reduced Downtime

Furthermore, carbide inserts offer excellent chip control, thanks to their superior chip-breaking capabilities. This minimizes the risk of chip buildup and tool jamming, leading to smoother and more efficient machining processes. With carbide inserts, manufacturers can reduce downtime and tool changeovers, increasing overall throughput and profitability.

Versatility and Adaptability

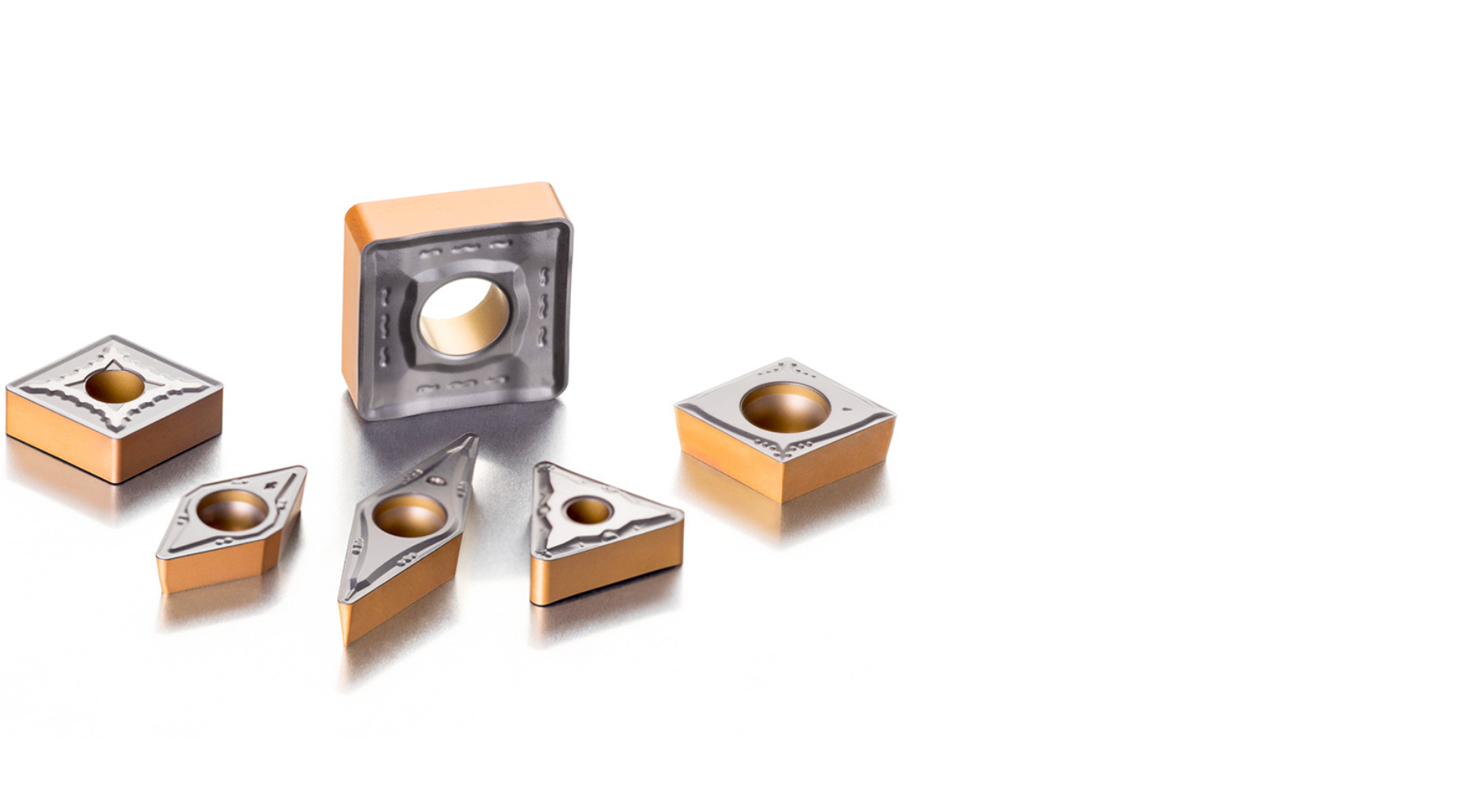

The versatility of carbide inserts is another key advantage that sets them apart from other cutting tools. They come in a wide range of shapes, sizes, and geometries, making them suitable for a variety of machining applications. Whether it’s turning, milling, drilling, or threading, carbide inserts can be tailored to meet specific machining requirements, providing manufacturers with flexibility and adaptability in their operations.

Conclusion

In conclusion, advanced carbide inserts offer a multitude of advantages that can help manufacturers optimize precision and efficiency in modern machining. Their exceptional hardness, heat resistance, chip control, and versatility make them indispensable tools for a wide range of industries. By incorporating carbide inserts into their machining processes, manufacturers can achieve higher levels of productivity, quality, and cost-effectiveness, ultimately gaining a competitive edge in today’s fast-paced manufacturing environment.